Product Description

|

Item

|

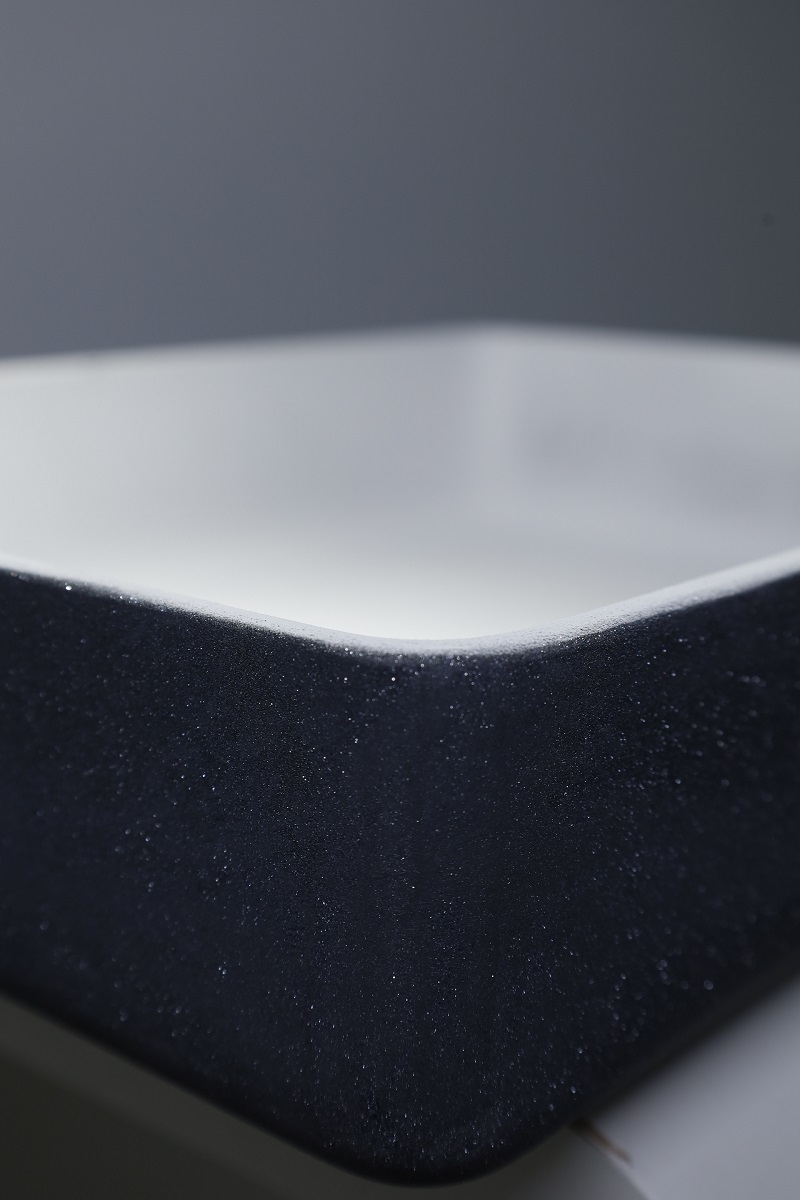

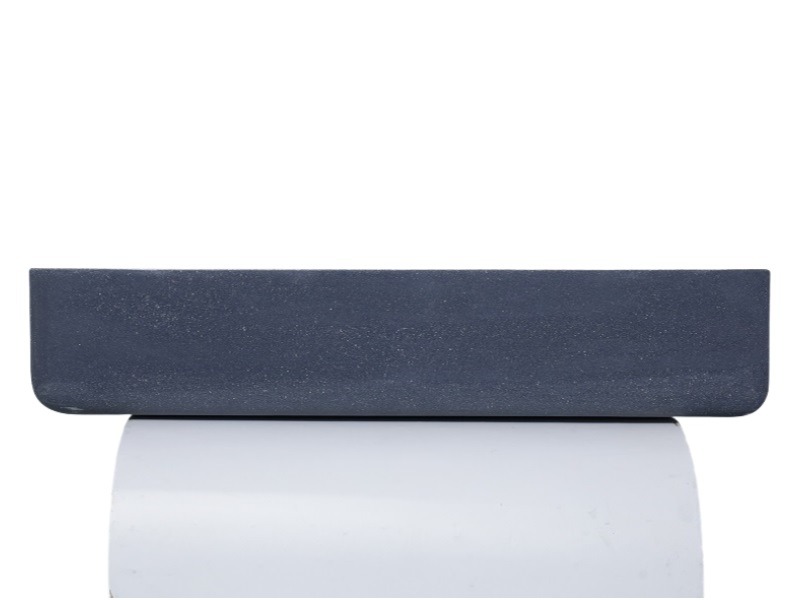

Sagger RSiC Acid And Alkali Resistant Alumina Coating

|

|

Sintering method

|

RSIC

|

|

Application

|

High Temperature Kilns

|

|

Delivery

|

About 30 days-45 days after payment

|

|

Size

|

Customized, according to your drawing

|

|

Payment

|

TT, Western union, Credit Card

|

|

Packing& Shipping

|

1. Each item is wrapped with oppbag and protective air bubble

2. Then put into the box/Pack with strong Cartons for shipping

3. We use different packing methods according to different products, or we can use customized packing.

|

|

项目 Item

|

单位 Unit

|

碳化硅 SIC

|

|

碳化硅含量 Sic contect

|

%

|

≥99

|

|

密度 Density

|

g/cm3

|

3.1~3.15

|

|

硬度 Hardness

|

HV0.5

|

≥2600

|

|

抗折强度 Flexural strength

|

MPa

|

≥400

|

|

耐温能力 Max working temperature

|

℃

|

1600

|

|

弹性模量 Modulus elasticity

|

GPa

|

400

|

|

热膨胀系数 Expansion coefficient

|

10-6/C

|

4.0

|

|

热导率 Thermal conductivity

|

w/(m.k)

|

30~110

|

|

显气孔率 Apparent porosity

|

%

|

<0.2

|

|

抗压强度 Compressive strength

|

*10-4

|

3

|

|

项目

Item

|

单位

|

常压烧结碳化硅

SSIC

|

反应烧结碳化硅

RBSIC/SISIC

|

重结晶烧结碳化硅

RSIC

|

|

UNIT

|

DATA

|

DATA

|

DATA

|

|

|

最高使用温度

Max temperature of Application

|

℃

|

1600

|

1380

|

1650

|

|

密度

Density

|

g/cm3

|

>3.1

|

>3.02

|

>2.6

|

|

气孔性

Open Porosity

|

%

|

<0.1

|

<0.1

|

15%

|

|

抗弯强度

Bending Strength

|

Mpa

|

>400

|

250(20℃)

|

90-100(20℃)

|

|

Mpa

|

|

280(1200℃)

|

100-120(1100℃)

|

|

|

弹性模量

Modulus of Elasticity

|

Gpa

|

420

|

330(20℃)

|

240

|

|

Gpa

|

|

300(1200℃)

|

|

|

|

热传导系数

Thermal Conductivity

|

W/m.k

|

74

|

45(1200℃)

|

24

|

|

热膨胀系数

Coefficient of Thermal Expansion

|

K-1x10-6

|

4.1

|

4.5

|

4.8

|

|

维式硬度

Vickers Hardness HV

|

Gpa

|

22

|

20

|

|

|

耐酸碱度

Acid Alkaline-proof

|

|

优(excellent)

|

优(excellent)

|

优(excellent)

|

|

Parameter

|

Measurements

|

RB SIC

|

SSIC

|

SSIC

|

|

Density

|

g/cm3

|

≥3.03

|

3.08~3.15

|

2.95~3.05

|

|

Indicated Porosity

|

%

|

≤1

|

≤1

|

≤1

|

|

Crystal Size

|

µm

|

≤10

|

≤10

|

≤10

|

|

Hardness

|

Rockwell

|

≥90

|

≥92

|

≥92

|

|

Compressive Strength

|

MPa

|

3000

|

3000

|

≥2200

|

|

Transverse Strength

|

MPa

|

≥350

|

400

|

≥200

|

|

Maximum Temperature

|

℃

|

1200

|

1600

|

1500

|

|

Elastic Modulus

|

GPa

|

350

|

400

|

≥250

|

|

Thermal Conductivity

|

W/m*k

|

30~130

|

30~130

|

30~130

|

|

Coefficient of Thermal Expansion

|

1 x 10-6 / ℃

|

4~5

|

4~5

|

4~5

|

|

Item

|

Unit

|

Al2O3

|

SIC

|

B4C

|

|

Density

|

g/cm3

|

≥3.5

|

≥3.14

|

≥2.46

|

|

Hardness

|

HV

|

≥1650

|

≥2400

|

≥2600

|

|

Flexure strength

|

MPa

|

≥290

|

≥380

|

≥340

|

|

Apparent porosity

|

%

|

0

|

<2

|

<2

|

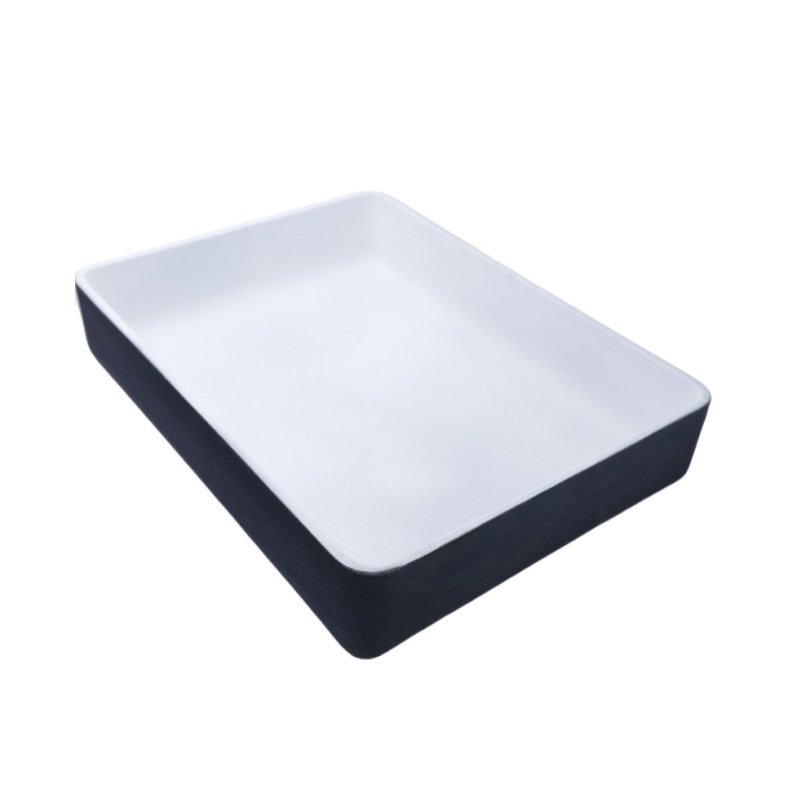

Introduction

Sagger RSiC Acid And Alkali Resistant Alumina Coating

Introduction of RSiC sagger

The core advantages of RSiC sagger

(1) Ultra high temperature stability

Temperature endurance limit: Long term endurance of 1650 ° C, far exceeding the aluminum oxide sagger (1600 ° C) and graphite sagger.

Case: When firing ZrB. – SiC ultra-high temperature ceramics, the lifespan of the RSiC sagger is more than three times that of graphite.

(2) Chemical inertness

Corrosion resistance: Resistant to the erosion of molten borides and hydrides (such as AI vapor in AIN sintering), its stability in HF/HCI atmosphere is better than that of alumina sagger.

Case: When firing fluoride transparent ceramics (such as CaF), there is no risk of oxidation reaction in the RSiC sagger.

(3) Uniformity of thermal field

Porous structure (15-20% porosity): promotes uniform infiltration of atmosphere and avoids density differences in the same part of ceramics;

Pores can serve as a thermal buffer layer, reducing thermal stress (crucial for large ceramic components)

(4) Low pollution

Purity>99.999%: Avoid impurities such as Fe and AI from migrating into the ceramic, which may affect the dielectric/mechanical properties.

FEATURES & BENEFITS

* RSiC sagger Thermal shock resistance

* RSiC sagger High thermal conductivity

* RSiC sagger High mechanical strength

* RSiC sagger Acid and alkali resistance

* RSiC sagger Wear resistance

|

High Temperature Kiln Equipment Industry

|

RSiC

|

|

SiC Content (%)

|

≥99%

|

|

Bulk Density (g/cm3)

|

2.65~2.75

|

|

Apparent Porosity (%)

|

<17

|

|

Room temperaturestrength (MPa)

|

90~100

|

|

Strengthat 1300℃(MPa)

|

100-110

|

|

Elasticity modulus at 20℃

|

240

|

|

Thermal Conductivity At 1200℃(W/mk)

|

36

|

|

Thermal Expansion x10-6/℃

|

4.6

|

|

Max Using Temperature(℃)

|

1650℃

|

|

Hardness At 20°C (Kg/mm2)

|

2000

|

Company Profile

Jiangsu Zitai Co.Ltd

1.A professional Team!

Zitai have a full service include ceramic forming,molding design and development, precision machining and precision detection technology and we have a professional techincal teams and our engineer works in this line more 20years. We are good at listening and understanding your real needs and can provide exclusive personal customization!

2.A good listener!

Take the good faith as the book, strives for the survival by the quality, serves the quality to win the customer trust,maitain the spirit of innovation and development, thoughtful after-sales service enterprises as the goal.

3.Professional production equipment

We have dozens of professional equipment in line with EU production standards.Can be customized with your different production needs, different materials for production. Due to the high operation of the equipment, the production cycle can be greatly shortened.

4.Rigorous inspection process

We will be in the production of products after the professional technical personnel for product quality review and tolerance measurement. To ensure that the products sent to your hands are the best quality products.

FAQ

Q:Are you a manufacturer or trading company ?

A:We are professional manufacturer and supplier in China.we have a professional technical team in this line.

Q:What’s the MOQ?

A:There is no limit on quantity, the quantity is more,the price is better.

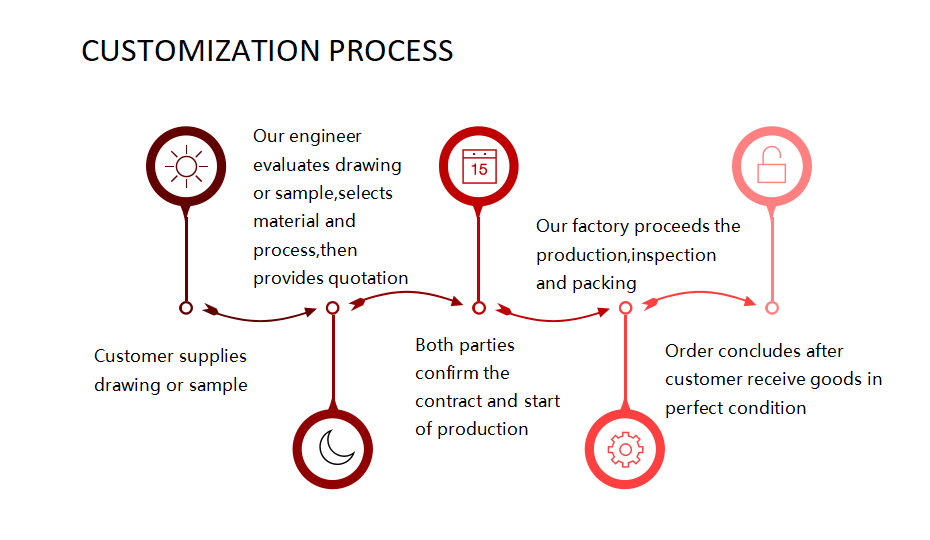

Q:Do you accept customized dimension?

A:Yes, we can produce ceramic parts per customer’s drawing.

Q:Can you supply a free sample?

A:We can supply a free sample to you within 3 days when we have an exsited size in our stock and the freight is collect.

We always send the sample before the mass production and keep the quality of the bulk goods is consistent with that of the sample.

Q:What about your after-sales service?

A:We have strict and professional QC team. We are always offering qualified products.

If the quality can not meet requirement, we will reproduce the qualified products or refund the payment.

Q:What is your payment term?

A:We mainly accept T/T, West Union, Credit card and L/C at sight.

Paypal will be available in the near future.

Reviews

There are no reviews yet.