Product Description

|

Item Name

|

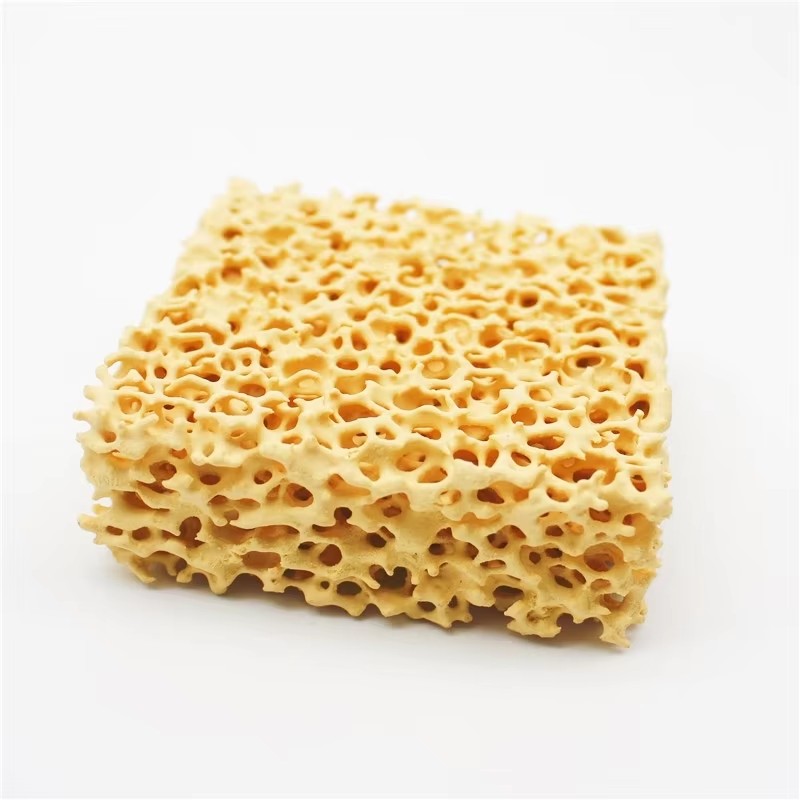

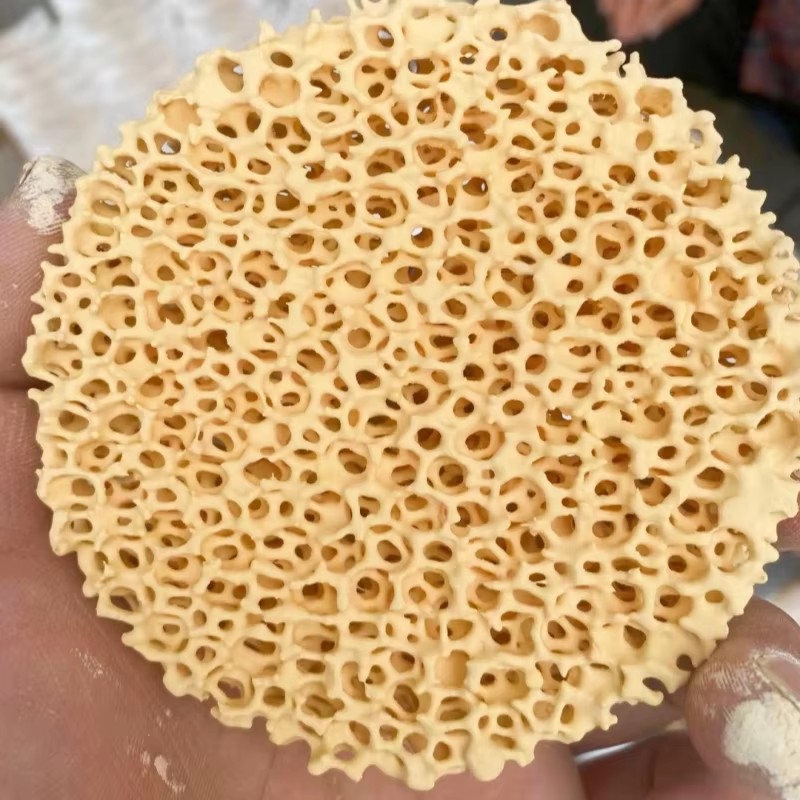

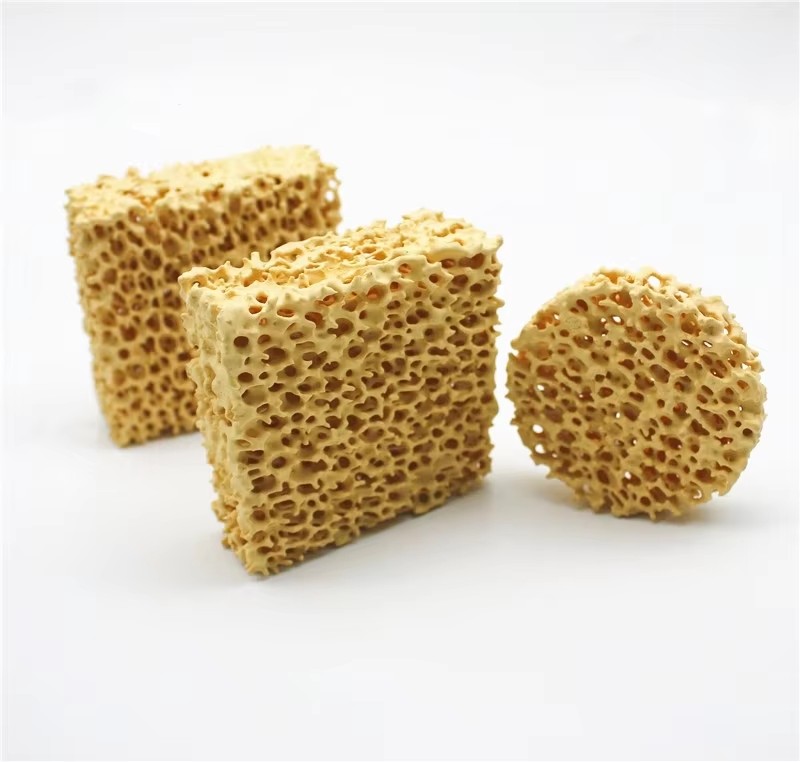

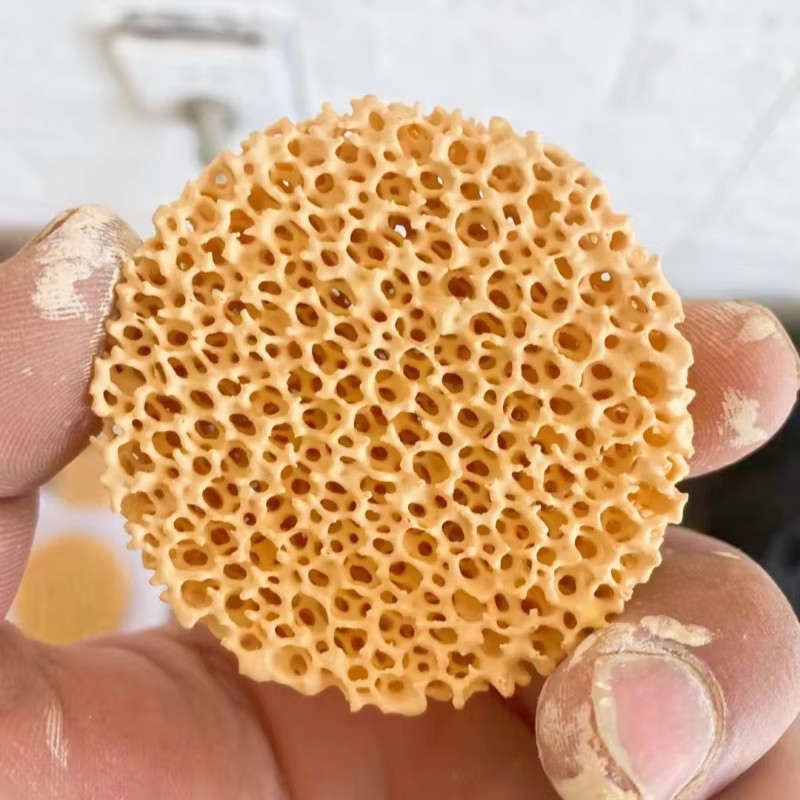

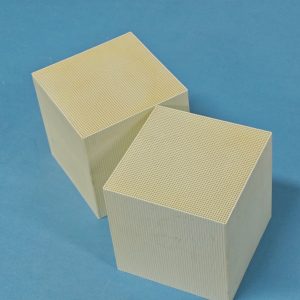

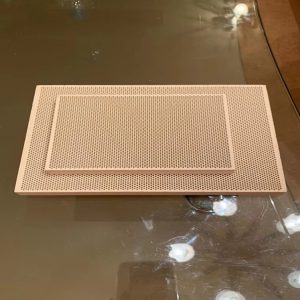

Zirconia Material Alumina Foam Ceramic Filter

|

|

Material

|

silicon carbide ,alumina ,zirconia

|

|

Thermal Shock Resistance

|

Not break after 6 times thermal shock testing

|

|

Temperature

|

1000-1700C

|

|

Payment

|

TT, Western union, Credit Card,Paypal

|

|

Shipping

|

Air Express (DHL/UPS/TNT/ FedEx),Sea transportation

|

|

Packing

|

1. Each item is wrapped with oppbag and protective air bubble 2. Then put into the box/Pack with strong Cartons for shipping

3. We use different packing methods according to different products, or we can use customized packing.

|

|

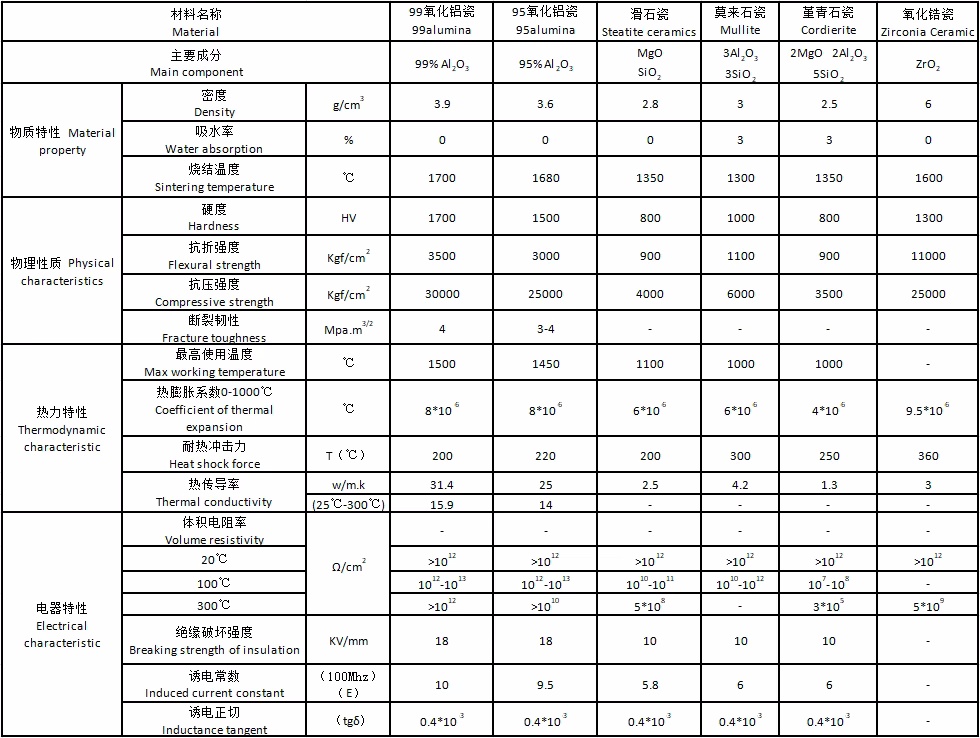

材质

Material

|

氧化铝

Alumina

|

碳化硅

Siicon Carbide

|

氧化锆

Zirconia

|

氧化镁

Mgo

|

|

颜色

Color

|

白色

White

|

深灰色

Dark Grey

|

黄色

Yellow

|

深黄色

Dark Yellow

|

|

工作温度

Applied Temp. (℃)

|

≤1200

|

≤1500

|

≤1700

|

≤1100

|

|

孔数

Pore Size(PPl) |

10,20,30

|

10,20,30

|

10,20,30

|

10,20,30

|

|

开孔率

Porosity(%) |

80~90

|

80~90

|

80~90

|

80~90

|

|

密度

Bulk Density(g/cm3)

|

0.35~0.55

|

0.45~0.65

|

1.0~1.5

|

0.8~1.2

|

|

抗压强度

Compressive strength(Mpa) |

≥0.8

|

≥1.0

|

≥1.5

|

≥1.2

|

Introduction

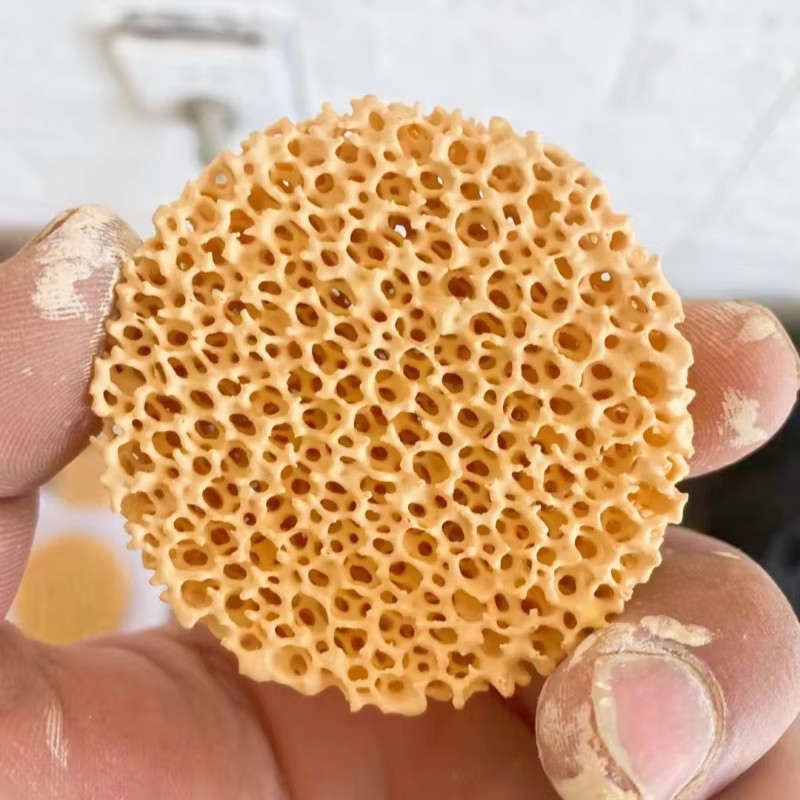

Zirconia Ceramic Foam Filter

Advantages:

Usage:

Company Profile

Jiangsu Zitai Co.Ltd

1.A professional Team!

Zitai have a full service include ceramic forming,molding design and development, precision machining and precision detection technology and we have a professional techincal teams and our engineer works in this line more 20years. We are good at listening and understanding your real needs and can provide exclusive personal customization!

2.A good listener!

Take the good faith as the book, strives for the survival by the quality, serves the quality to win the customer trust,maitain the spirit of innovation and development, thoughtful after-sales service enterprises as the goal.

3.Professional production equipment

We have dozens of professional equipment in line with EU production standards.Can be customized with your different production needs, different materials for production. Due to the high operation of the equipment, the production cycle can be greatly shortened.

4.Rigorous inspection process

We will be in the production of products after the professional technical personnel for product quality review and tolerance measurement. To ensure that the products sent to your hands are the best quality products.

FAQ

Q:Are you a manufacturer or trading company ?

A:We are professional manufacturer and supplier in China.we have a professional technical team in this line.

Q:What’s the MOQ?

A:There is no limit on quantity, the quantity is more,the price is better.

Q:Do you accept customized dimension?

A:Yes, we can produce ceramic parts per customer’s drawing.

Q:Can you supply a free sample?

A:We can supply a free sample to you within 3 days when we have an exsited size in our stock and the freight is collect.

We always send the sample before the mass production and keep the quality of the bulk goods is consistent with that of the sample.

Q:What about your after-sales service?

A:We have strict and professional QC team. We are always offering qualified products.

If the quality can not meet requirement, we will reproduce the qualified products or refund the payment.

Q:What is your payment term?

A:We mainly accept T/T, West Union, Credit card and L/C at sight.

Paypal will be available in the near future.

Reviews

There are no reviews yet.