Product Description

|

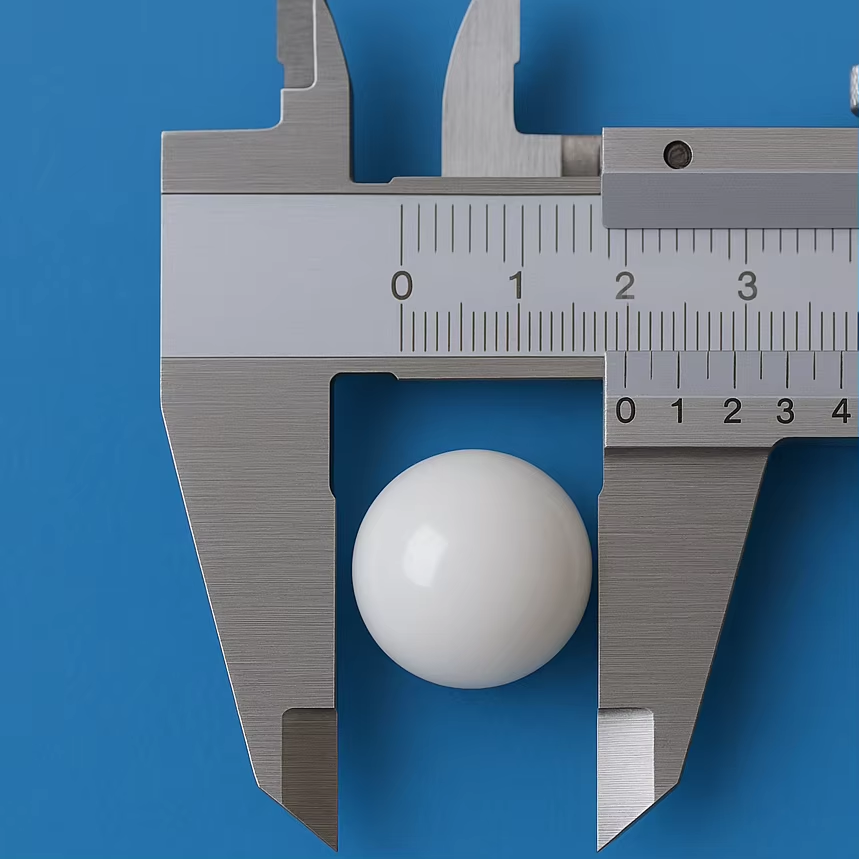

Item Name

|

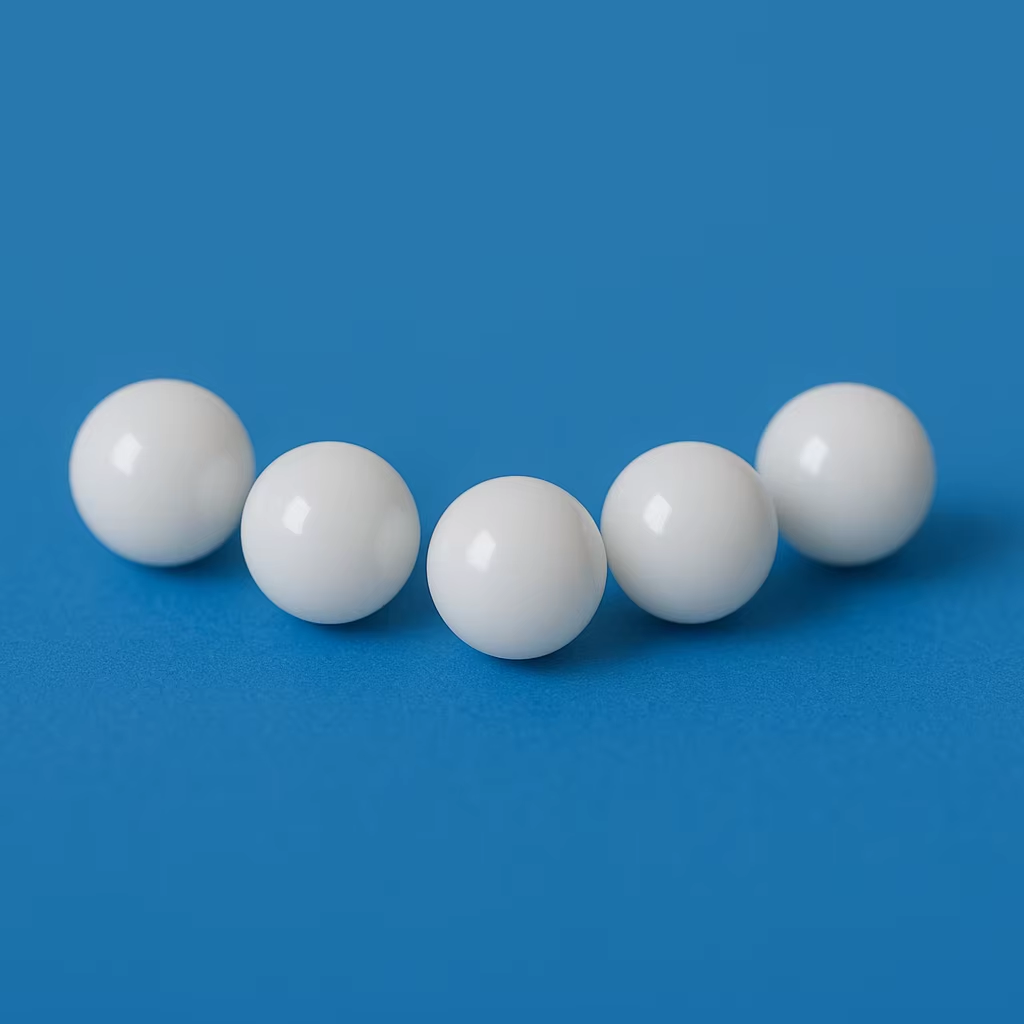

Zirconia Beads

|

|

Material

|

zirconia

|

|

Color

|

white

|

|

Payment

|

TT, Western union, Credit Card,Paypal

|

|

Shipping

|

Air Express (DHL/UPS/TNT/ FedEx),Sea transportation

|

|

Packing

|

1. Each item is wrapped with oppbag and protective air bubble 2. Then put into the box/Pack with strong Cartons for shipping

3. We use different packing methods according to different products, or we can use customized packing.

|

Introduction

Zirconia Beads

Zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high flexural strength, high wear resistance, excellent thermal insulation performance, and a thermal expansion coefficient close to that of steel. Mainly include: Y-TZP grinding balls, dispersing and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, wire drawing dies and cutting tools, clothing buttons, watch cases and watches Belts, bracelets and pendants, ball bearings, golf light bats and other wear-resistant parts at room temperature.

This dense advanced ceramics material is typically precision ground using conventional diamond cutters and wheels.

Machines used for precision grinding include:

6. ID grinders

|

Zirconia Beads Technical Specifications Table

|

||

|

Property

|

Specification

|

Remarks

|

|

Material Type

|

Material Type Yttria-Stabilized Zirconia (YSZ)

|

ZrO₂ (94-95%) + Y₂O₃ (5-6%)

|

|

Crystal Structure

|

Crystal Structure Tetragonal Phase Dominant

|

Transformation toughening mechanism

|

|

Density

|

Density 6.00–6.05 g/cm³

|

Higher than alumina (3.9 g/cm³) or glass (2.5 g/cm³)

|

|

Hardness(Vickers)

|

≥1,200 HV

|

Retains sphericity under high-pressure grinding

|

|

Wear Rate

|

<0.01% per 100 hrs

|

5-10x longer lifespan than alumina beads

|

|

Chemical Stability

|

Inert to acids/alkalis (pH 1–14)

|

Suitable for corrosive slurries

|

|

Color

|

Pure White

|

No pigment contamination

|

|

Available Sizes

|

0.1 mm – 5.0 mm

|

Common sizes: 0.3 mm, 0.5 mm, 0.8 mm, 1.0 mm

|

|

Tolerance

|

±0.01 mm (for <1.0 mm)

|

Precision-grade sphericity

|

|

Applications

|

• Nano-grinding (≤0.1 μm)

• Pigments/Inks

• Battery materials (LFP/NMC)

• Ceramic capacitors (MLCC)

|

Low contamination critical processes

|

|

Parameters of Zirconia(Zr02)Ceramic

|

|||

|

Mechanical properties

|

Fracture toughness

|

Mpa.m3/2

|

3-4

|

|

Compressive strength

|

Kgf/cm2

|

25000

|

|

|

Flexural strength

|

Kgf/cm2

|

11000

|

|

|

Hardness

|

HV

|

1300

|

|

|

Physical properties

|

Sintering temperature

|

℃

|

1600

|

|

Moisture absorption

|

%

|

0

|

|

|

Density

|

g/cm3

|

6

|

|

|

Thermal properties

|

Thermal conductivity

|

w/m.k (25°c-300°c)

|

14

|

|

Thermal shock resistance

|

T(°C)

|

360

|

|

|

Thermal expansion coefficient(0-10000C)

|

/℃

|

9.5X10.6

|

|

|

Maximum use temperature

|

℃

|

1450

|

|

|

Electrical properties

|

Dielectric constant (100MHz)

|

(E)

|

9.5

|

|

Dielectric breakdown strength

|

KV/mm

|

18

|

|

|

20℃

|

Ohm/cm2

|

>1012

|

|

|

100℃

|

1012-1013

|

||

|

300℃

|

5X109

|

||

|

Volume resistivity

|

–

|

||

Company Profile

Jiangsu Zitai Co.Ltd

1.A professional Team!

Zitai have a full service include ceramic forming,molding design and development, precision machining and precision detection technology and we have a professional techincal teams and our engineer works in this line more 20years. We are good at listening and understanding your real needs and can provide exclusive personal customization!

2.A good listener!

Take the good faith as the book, strives for the survival by the quality, serves the quality to win the customer trust,maitain the spirit of innovation and development, thoughtful after-sales service enterprises as the goal.

3.Professional production equipment

We have dozens of professional equipment in line with EU production standards.Can be customized with your different production needs, different materials for production. Due to the high operation of the equipment, the production cycle can be greatly shortened.

4.Rigorous inspection process

We will be in the production of products after the professional technical personnel for product quality review and tolerance measurement. To ensure that the products sent to your hands are the best quality products.

FAQ

Q:Are you a manufacturer or trading company ?

A:We are professional manufacturer and supplier in China.we have a professional technical team in this line.

Q:What’s the MOQ?

A:There is no limit on quantity, the quantity is more,the price is better.

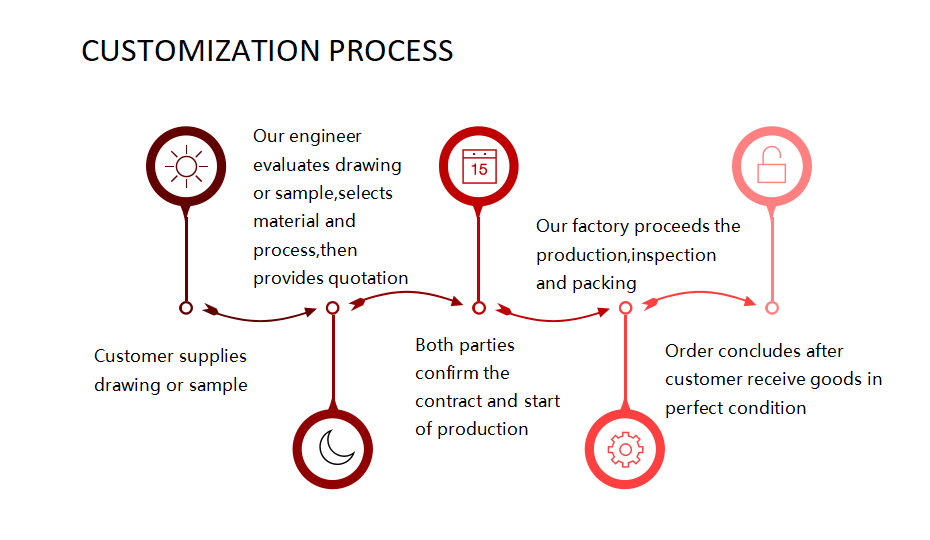

Q:Do you accept customized dimension?

A:Yes, we can produce ceramic parts per customer’s drawing.

Q:Can you supply a free sample?

A:We can supply a free sample to you within 3 days when we have an exsited size in our stock and the freight is collect.

We always send the sample before the mass production and keep the quality of the bulk goods is consistent with that of the sample.

Q:What about your after-sales service?

A:We have strict and professional QC team. We are always offering qualified products.

If the quality can not meet requirement, we will reproduce the qualified products or refund the payment.

Q:What is your payment term?

A:We mainly accept T/T, West Union, Credit card and L/C at sight.

Paypal will be available in the near future.

Reviews

There are no reviews yet.