Product Description

|

Thickness(mm)

|

Size(inch)

|

|||||

|

50.8*50.8

|

114.3*114.3

|

120*120

|

140*190

|

245*254

|

300*300

|

|

|

0.25

|

√

|

√

|

√

|

√

|

√

|

√

|

|

0.381

|

√

|

√

|

√

|

√

|

√

|

√

|

|

0.5

|

√

|

√

|

√

|

√

|

√

|

√

|

|

0.635

|

√

|

√

|

√

|

√

|

√

|

√

|

|

1

|

√

|

√

|

√

|

√

|

√

|

√

|

|

1.5

|

√

|

√

|

√

|

√

|

√

|

√

|

|

2

|

√

|

√

|

√

|

√

|

√

|

√

|

|

项目Project

|

单位 Unit

|

参数 Parameter

|

|

颜色 Color

|

–

|

Gray/Cream

|

|

热导率 Thermal conductivity

|

20℃ W/m.k

|

≥170

|

|

抗弯强度 Flexural strength

|

MPa

|

>350

|

|

表面粗糙度 Warpage

|

‰

|

<2.5

|

|

体积密度 Bulk density

|

g/cm3

|

>3.3

|

|

热膨胀系数 Coefficient of liner expansion

|

10-6mm/℃

|

4.6

|

|

体积电阻 Volume resistance

|

Ω*cm

|

1.5*1014

|

|

介电常数 Dielectric constant

|

1MHz

|

9.0

|

|

介电损耗 Dielectric loss

|

1 MHz

|

4.6*10-4

|

|

介电强度 Dielectric strength

|

KV/mm

|

>15

|

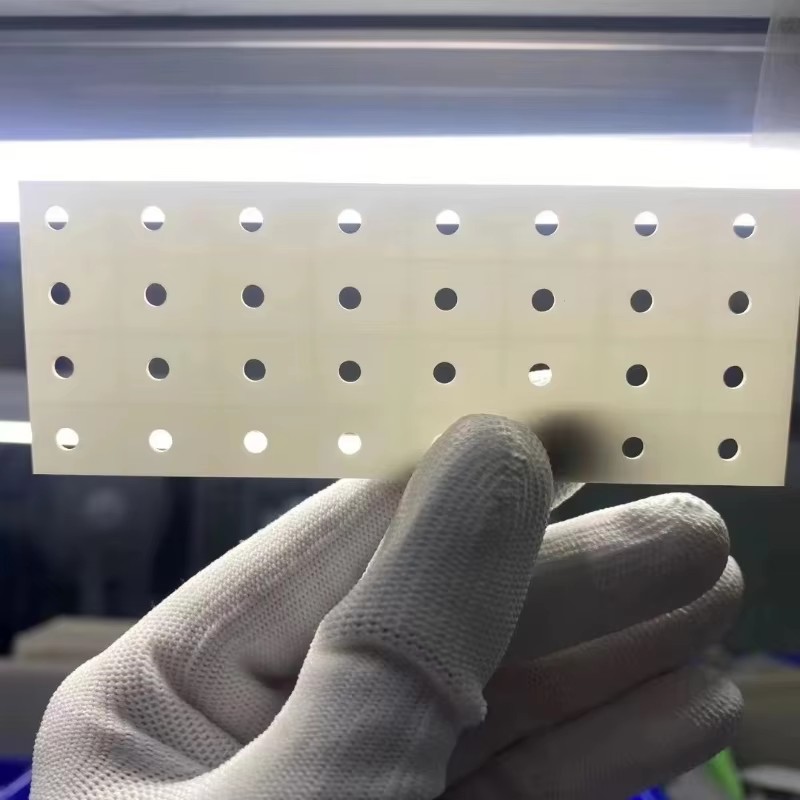

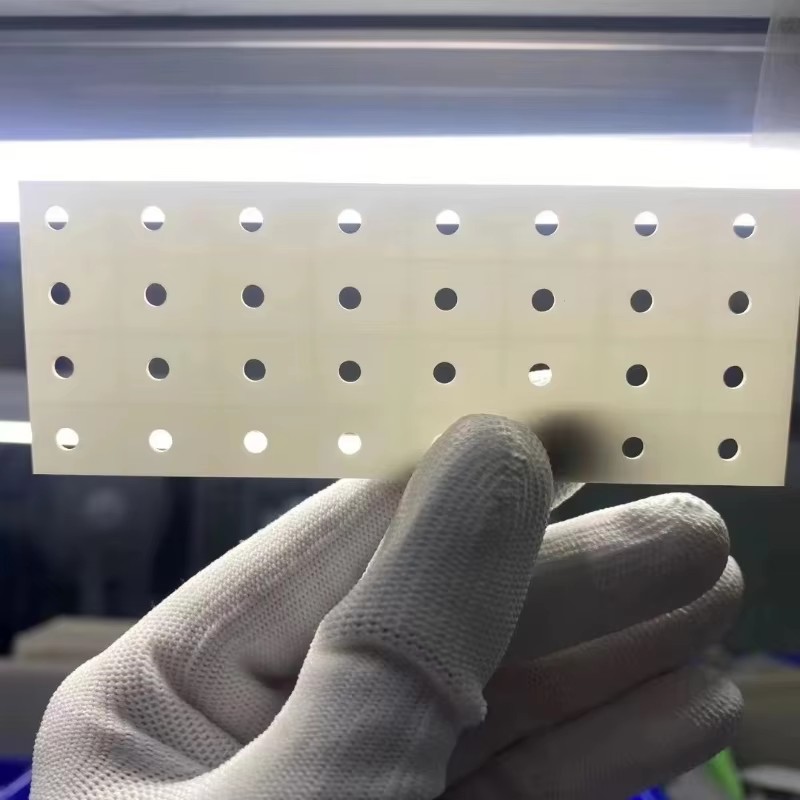

Introduction

Aluminum nitride substrate is a new type of ceramic substrate, which has excellent thermal conductivity, high electrical insulation and thermal expansion similar to silicon. It can be used as a high thermal conductivity substrate material for power transistor module substrate, laser diode mounting substrate, IC packaging and other fields.Aluminum nitride substrate can also be used as electronic film material, applied in microelectronics and optoelectronics technology. Inaddition, due to its excellent corrosion resistance to halogen gases, aluminum nitride can also be used as a component in semiconductor manufacturing equipment.

Aluminum Nitride (AlN) is a advanced ceramic material with a range of notable properties and applications.

Key Properties

-

Thermal Conductivity: High (∼170-200 W/m·K), surpassing alumina (Al₂O₃), making it ideal for heat dissipation.

-

Electrical Insulation: Excellent dielectric properties, suitable for electronic substrates.

-

Mechanical: Hard, brittle, and refractory with a high melting point (~2200°C).

-

Chemical Stability: Resists oxidation but hydrolyzes in moisture:

Reaction: AlN + 3H₂O → Al(OH)₃ + NH₃↑ (requires dry handling). -

Piezoelectricity: Useful in sensors and resonators.

Synthesis

-

Methods:

-

Direct nitridation of aluminum powder with nitrogen at high temperatures.

-

Chemical Vapor Deposition (CVD) for thin films.

-

Sintering with additives (e.g., Y₂O₃) to enhance density, though purity is critical for optimal performance.

-

Applications

-

Electronics: Substrates for semiconductors, LED packaging, and heat sinks in power modules.

-

Optoelectronics: Used in UV LEDs and laser diodes due to wide bandgap (6.2 eV).

-

Piezoelectric Devices: Sensors, acoustic wave resonators, and MEMS.

-

Industrial: Crucibles for molten metals, composite fillers, and protective coatings.

Company Profile

Jiangsu Zitai Co.Ltd

1.A professional Team!

Zitai have a full service include ceramic forming,molding design and development, precision machining and precision detection technology and we have a professional techincal teams and our engineer works in this line more 20years. We are good at listening and understanding your real needs and can provide exclusive personal customization!

2.A good listener!

Take the good faith as the book, strives for the survival by the quality, serves the quality to win the customer trust,maitain the spirit of innovation and development, thoughtful after-sales service enterprises as the goal.

3.Professional production equipment

We have dozens of professional equipment in line with EU production standards.Can be customized with your different production needs, different materials for production. Due to the high operation of the equipment, the production cycle can be greatly shortened.

4.Rigorous inspection process

We will be in the production of products after the professional technical personnel for product quality review and tolerance measurement. To ensure that the products sent to your hands are the best quality products.

FAQ

Q:Are you a manufacturer or trading company ?

A:We are professional manufacturer and supplier in China.we have a professional technical team in this line.

Q:What’s the MOQ?

A:There is no limit on quantity, the quantity is more,the price is better.

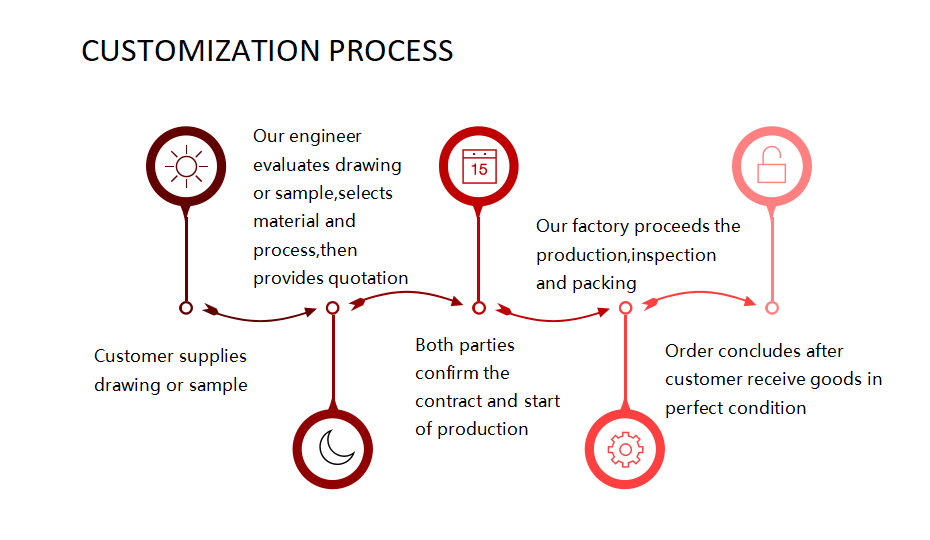

Q:Do you accept customized dimension?

A:Yes, we can produce ceramic parts per customer’s drawing.

Q:Can you supply a free sample?

A:We can supply a free sample to you within 3 days when we have an exsited size in our stock and the freight is collect.

We always send the sample before the mass production and keep the quality of the bulk goods is consistent with that of the sample.

Q:What about your after-sales service?

A:We have strict and professional QC team. We are always offering qualified products.

If the quality can not meet requirement, we will reproduce the qualified products or refund the payment.

Q:What is your payment term?

A:We mainly accept T/T, West Union, Credit card and L/C at sight.

Paypal will be available in the near future.

-300x300.jpg)

Reviews

There are no reviews yet.